EP.41 THE FASTEST BRICKLAYING ROBOT

An autonomous excavator, ABB with the most precise cobot & much more...

Autonomous excavator builds a wall of stones! 🗿

Building a wall by stacking irregularly shaped boulders is physically and mentally challenging. However, a robotic excavator named HEAP has accomplished this feat without human involvement.

HEAP (Hydraulic Excavator for an Autonomous Purpose) is a 12-ton Menzi Muck M545 walking excavator researchers at ETH Zurich modified. Equipped with GNSS positioning, LiDAR sensors, and machine vision technology, HEAP autonomously scanned a construction site, mapped boulders, and lifted them into place to build a massive dry-stone wall.

Dry-stone walls are made by stacking stones without mortar, and HEAP constructed a 6-meter-high, 65-meter-long wall using only locally sourced boulders. It assessed each boulder's shape, weight, and center of gravity to ensure stable placement, stacking 20 to 30 boulders in each building session.

This system allows for the efficient use of local materials, reducing the environmental impact of transporting stones. The success of HEAP demonstrates the potential for autonomous machines to tackle complex construction tasks that would typically require human labor.

The most precise cobot on the market! 😮💨

ABB Robotics has just launched an exciting new feature called Ultra Accuracy for their GoFa™ cobots, offering a tenfold increase in precision compared to other robots. This new level of accuracy—down to just 0.03 millimeters—makes GoFa cobots ideal for industries like electronics, automotive, aerospace, and metal fabrication.

Whether it's gluing, laser welding, or cutting, these robots can handle complex tasks with unmatched precision, ensuring consistent product quality. The best part? GoFa cobots are easy to integrate into existing production lines, with no need for expensive modifications. Their compact design and full 6D motion make them highly flexible, perfect for businesses looking to automate.

Plus, with ABB's Ultra Accuracy feature, production is faster and smoother, thanks to factory pre-calibration. The powerful combination of Ultra Accuracy and RobotStudio® enables the programming of applications offline, with a 99% match between the simulation and reality. ABB's new feature is available for both new and existing GoFa cobots, making high-precision automation more accessible than ever.

Read more here → MOST PRECISE COBOT

The fastest bricklaying robot 🧱

A new player in construction has landed on American shores. Meet the Hadrian X, a robotic truck equipped with a 105-foot (32-meter) telescopic boom arm that can lay bricks faster than any human worker.

Developed by Australian robotics company FBR, the Hadrian X is designed to build entire homes with incredible speed and precision. Capable of stacking 500 masonry blocks per hour, this robot can construct a full-sized house in just two days. Now, it's arrived in Florida to demonstrate its capabilities.

The Hadrian X operates by loading pallets of construction blocks, each weighing up to 99 pounds (45 kg), into its system. The blocks are sent down a chute on the boom arm, coated with a quick-dry adhesive, and placed by a variable gripper. With its long reach, the robot can construct structures up to three stories tall. Unlike human workers, it doesn’t take breaks and can work in various weather conditions, making it a reliable 24/7 builder.

The arrival of Hadrian X in Florida is part of a joint venture between FBR and CRH Ventures Americas, Inc., a subsidiary of CRH plc, one of the largest concrete block suppliers in the U.S. The robot will first undergo a site acceptance test in Fort Meyers, demonstrating its brick-laying efficiency. If successful, Hadrian X will build between five and 10 single-story homes as part of a trial program.

Should the partnership go well, CRH Ventures plans to phase in up to 300 Hadrian X units across the U.S., potentially transforming how entire communities are built.

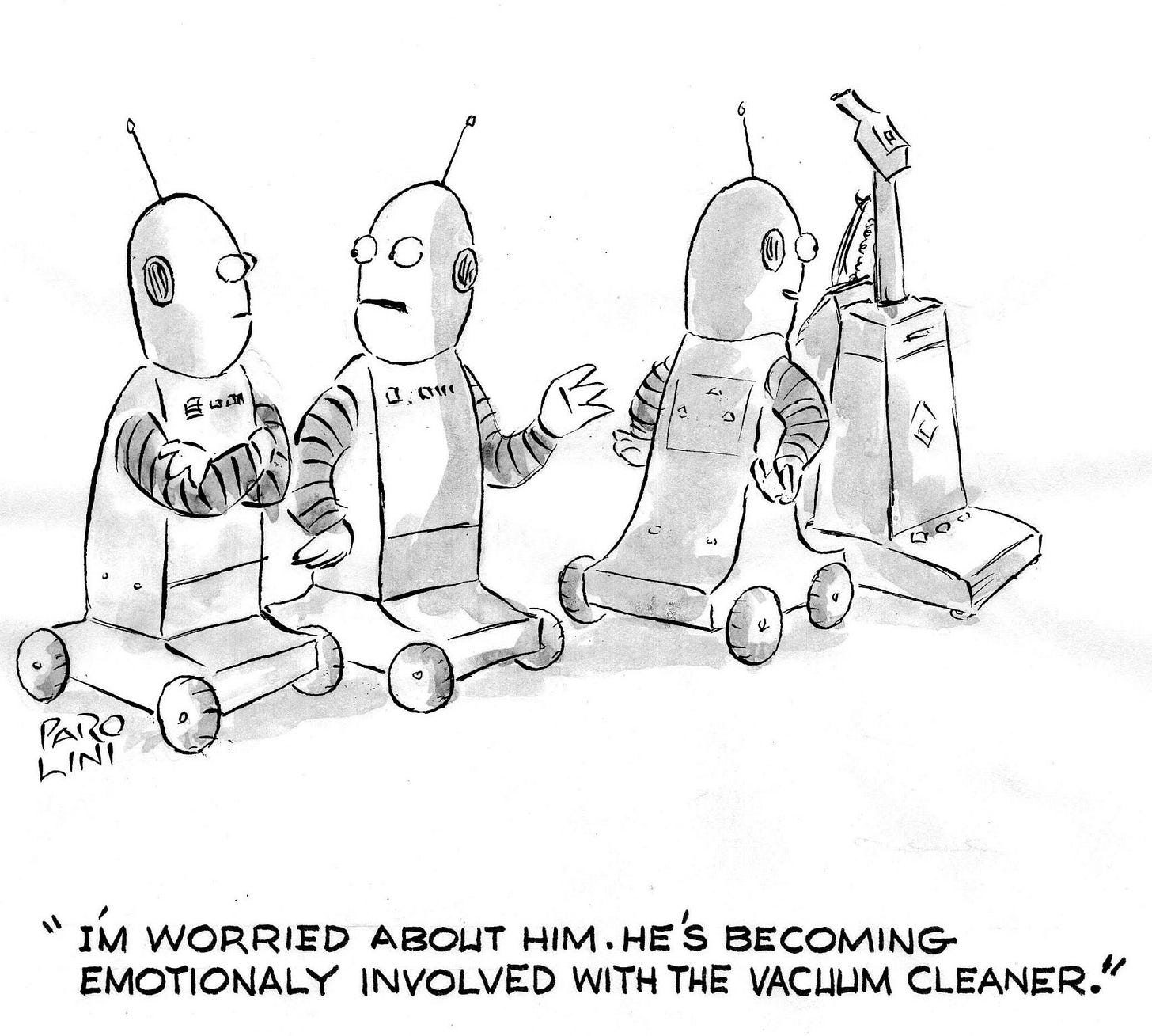

Meme of the week 🤖

Well, well well..

Build robots with Applied AI! 🧬

After watching this live stream, you will be able to:

Design, test, and deploy AI applications for robots, Cobots, AMRs, UAVs, etc.

Streamline development with Model-Based Design tools.

Insights Include:

Command robots with AI chatbots (ChatGPT, Bard).

Detect and classify objects using deep learning.

Efficient motion planning and control with reinforcement learning.

Deploy CUDA-optimized ROS nodes for deep learning.

A wheeled home service robot 🛞🏡

Tencent’s new robot has options for getting around.

The Chinese tech giant Tencent has introduced its latest innovation, The Five, also known as Xiao Wu. This fifth-generation robot uses a unique hybrid design, switching between walking on two legs and rolling on wheels, depending on the terrain and speed needed.

The robot is designed for everyday environments like homes and elderly care facilities. It walks upright at slower speeds using its legs and switches to its wheels when faster movement is required. It can even fold into a compact position when necessary.

One of the key features of The Five is its large-area tactile skin, which allows the robot to sense and interact with objects. This, combined with its safety features, ensures that The Five can safely navigate and work alongside humans in real-world settings.

Tencent’s focus on adaptability is evident, with the robot’s ability to switch movement modes and adjust to different environments, making it a versatile tool for complex tasks.