EP.45 A WHEELED ROBOTDOG BUILT FOR OFF-ROAD

An update from humanoids working in BMW factory, a mobile manipulator by Cobot, new statistics from IFR & much more...

BMW testing the humanoidal robots (update) 🦿

Figure AI’s humanoid robot, Figure 02, has demonstrated groundbreaking efficiency at BMW’s Spartanburg plant, achieving a 400% speed increase and a sevenfold improvement in success rate. Performing up to 1,000 precision placements daily, the robot autonomously handles tasks like high-precision sheet metal insertion with millimeter-level accuracy.

Founder Brett Adcock highlighted the complexity of the operation, which required reducing cycle times by four minutes while maintaining flawless precision. While initial tests were successful, Figure 02 is set to return to BMW’s facility in early 2025 as the company explores further collaboration.

Backed by $675 million in funding from industry leaders like NVIDIA and Microsoft, Figure is poised to revolutionize industrial automation with even greater efficiencies expected in the near future.

Robotics helping advance neurological disease research 🦠

At Texas Children’s Hospital, ABB Robotics has introduced the world's first automation system to aid the study of neurological diseases like Alzheimer’s, Huntington’s, and Parkinson’s. The innovative solution uses ABB’s YuMi (dual-arm cobot) to automate the transfer of fruit flies without anesthetization—a pioneering achievement in medical research.

Previously, transferring fruit flies between vials required immobilizing them with anesthetics such as carbon dioxide, a time-consuming step that risked altering their behavior and skewing results. By mimicking human precision, YuMi performs the task without the need for sedation. Researchers can now focus on critical tasks such as analyzing data or testing drug efficacy, improving efficiency and accuracy.

The YuMi cobot is equipped with advanced sensors and a dual-arm system, allowing it to perform complex actions like vial handling, barcode scanning, and labeling in one seamless process. Its compact size and collaborative design make it safe to work alongside humans, eliminating the need for safety barriers.

This automated solution has not only improved productivity by saving researchers 20% of their time but also enhanced data quality by preserving the flies’ natural state during experiments.

Read more here → Full success story

There is a new ‘cobot’ in the town! 🧠🤖

Cobot has publicly revealed Proxie, its highly-anticipated mobile manipulator, marking a significant step forward in autonomous, yet collaborative robotics. Founded by Brad Porter in 2022, the Santa Clara-based company is bringing Proxie to manufacturing, supply chain, and healthcare workflows.

Proxie features a swerve-drive base for smooth, holonomic motion, allowing it to navigate efficiently and align with shelving units or carts. The robot can pull carts through facilities and the company is already working with customers including Maersk, Moderna, Mayo Clinic, and Tampa General Hospital. Porter, former Amazon VP of Robotics, designed Proxie with warehouse efficiency in mind, offering a lower-cost, less complex alternative to humanoid robots for practical tasks.

With a dual-arm manipulator in development and $100 million in Series B funding, Proxie is set to redefine collaborative robotics.

Who said it must be a bipedal humanoid to help people out with mundane tasks?

Global Robot Density in factories doubles in seven years 📊

According to the International Federation of Robotics (IFR), factories worldwide are adopting robots at a record pace. The average global robot density in manufacturing reached 162 units per 10,000 employees in 2023, more than double the 74-unit average recorded in 2016.

Europe leads in regional robot density with 219 units per 10,000 employees, followed by North America with 197 units and Asia with 182. The Republic of Korea remains the global leader in industrial robot adoption, with 1,012 robots per 10,000 employees, followed by Singapore and China.

China’s rapid investment in automation has propelled it to third place globally, surpassing Germany and Japan. The U.S., with 295 robots per 10,000 employees, ranked eleventh in 2023, falling out of the top 10 despite steady growth.

Read more here → IFR Robot Density

Robot density in the manufacturing industry in 2023, Source: IFR

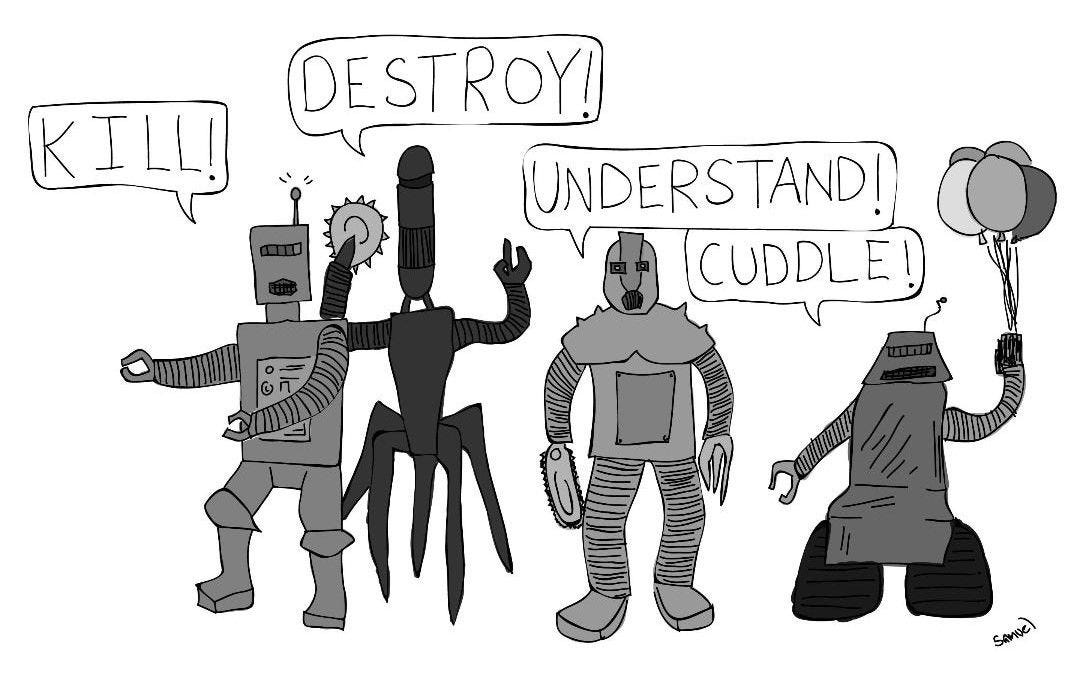

Meme of the week 🤖

Aww, these robots…

Build a cobot with MATLAB! 🤖

The course explores the development of a collaborative robot system to meet customer needs through a human-robot coworking environment, emphasizing multimodal control and adaptive dynamic control techniques.

Introduction to the need for flexible robotics systems in satisfying diverse customer demands.

Development of a robot hand incorporating multiple sensors using Model-Based Design with MATLAB® and Simulink®.

Integration of virtual and real control structures for seamless implementation.

Demonstration of robot arm modeling, trajectory planning, and simulation using Robotics System Toolbox™ and ROS Toolbox.

All-terrain robot dog! 🏔️

DEEP Robotics has previewed its newest quadruped robot, Lynx, a wheeled robodog built for extreme off-road performance. In a teaser video, the Lynx can be seen tackling steep slopes, climbing over large obstacles, bounding down stairs on two wheels, and racing across dirt tracks with impressive speed and control.

Unlike traditional pad-footed quadrupeds, the Lynx uses wheels to navigate rugged terrain at higher speeds while maintaining stability. It combines multiple modes, locking its wheels for climbing or rolling over loose gravel and steep inclines, showcasing its versatility ahead of its official launch.

Expected applications include search and rescue, mapping, and equipment transport, building on the capabilities of DEEP Robotics’ current lineup of their robots.