EP.58 A HUMANOID THAT RUNS, CRAWLS AND BREAKDANCES

A new collaborative helper for warehouses, a squirrel-inspired robot & much more...

Atlas robot is breakdancing! 🕺🏻

Boston Dynamics has once again demonstrated its dominance in humanoid robotics with a new video showcasing the latest advancements in Atlas' mobility. The footage features the swivel-jointed humanoid executing smooth, precise movements, including running, cartwheeling, and even breakdancing—pushing the boundaries of robotic agility.

While many companies, such as Tesla, Figure, Sanctuary, and Agility, prioritize practical applications like object manipulation and task execution, Boston Dynamics continues to refine its robots' athleticism. Though flashy, these mobility breakthroughs could pave the way for more advanced real-world applications requiring balance, dexterity, and adaptability.

As humanoid robots rapidly evolve from their early, unstable movements to fluid, confident navigation of human environments, the progress is astonishing and a glimpse into the future of robotics.

New AI-enabled picking robots from ABB! 🧦

ABB has expanded its Item Picking family with two new AI-powered functional modules designed to improve item singulation, picking, and sorter induction in logistics and e-commerce. The Robotic Fashion Inductor and Robotic Parcel Inductor use ABB’s AI-based vision technology to process randomly arranged items with high accuracy and efficiency.

The Robotic Fashion Inductor can handle polybagged apparel and accessories at speeds of up to 1,300 picks per hour. The Robotic Parcel Inductor processes small parcels, including boxes, bags, and envelopes, at up to 1,500 picks per hour in logistics centers. Both modules achieve an industry-leading picking accuracy of over 99.5 percent.

ABB’s motion planning software ensures collision-free path planning for each pick and placement. The AI system can also detect and reject non-inducible items like spherical or cylindrical products. Designed for rapid deployment, these modules come pre-integrated, reducing commissioning time to as little as one week.

By providing a complete solution—including robotic hardware, application software, and global after-sales support—ABB simplifies automation implementation and helps companies increase throughput, reduce errors, and address labor shortages in logistics and supply chain operations.

🦾 Feature sponsorship with ABB Robotics

Smarter more collaborative warehouses with Carter Pro! 🧠

Robust.AI's Carter™ Pro platform offers a multi-functional warehouse solution for fulfillment picking, point-to-point transport, and mobile sortation - operating within a single software-defined platform. With deployments across multiple warehouses, Carter streamlines workflows, reduces costs, and adapts to shifting demands without extra hardware investments.

Carter optimizes warehouse operations without requiring major infrastructure changes. It seamlessly transitions between tasks, maximizing automation efficiency. Unlike traditional warehouse robots, Robust.AI prioritizes human-robot collaboration and AI-driven optical navigation, avoiding costly LiDAR. This makes Carter a flexible, cost-effective solution for modern logistics.

Robust.AI and DHL continue to grow their partnership, expanding across multiple locations and working to define the future of human-robot collaboration.

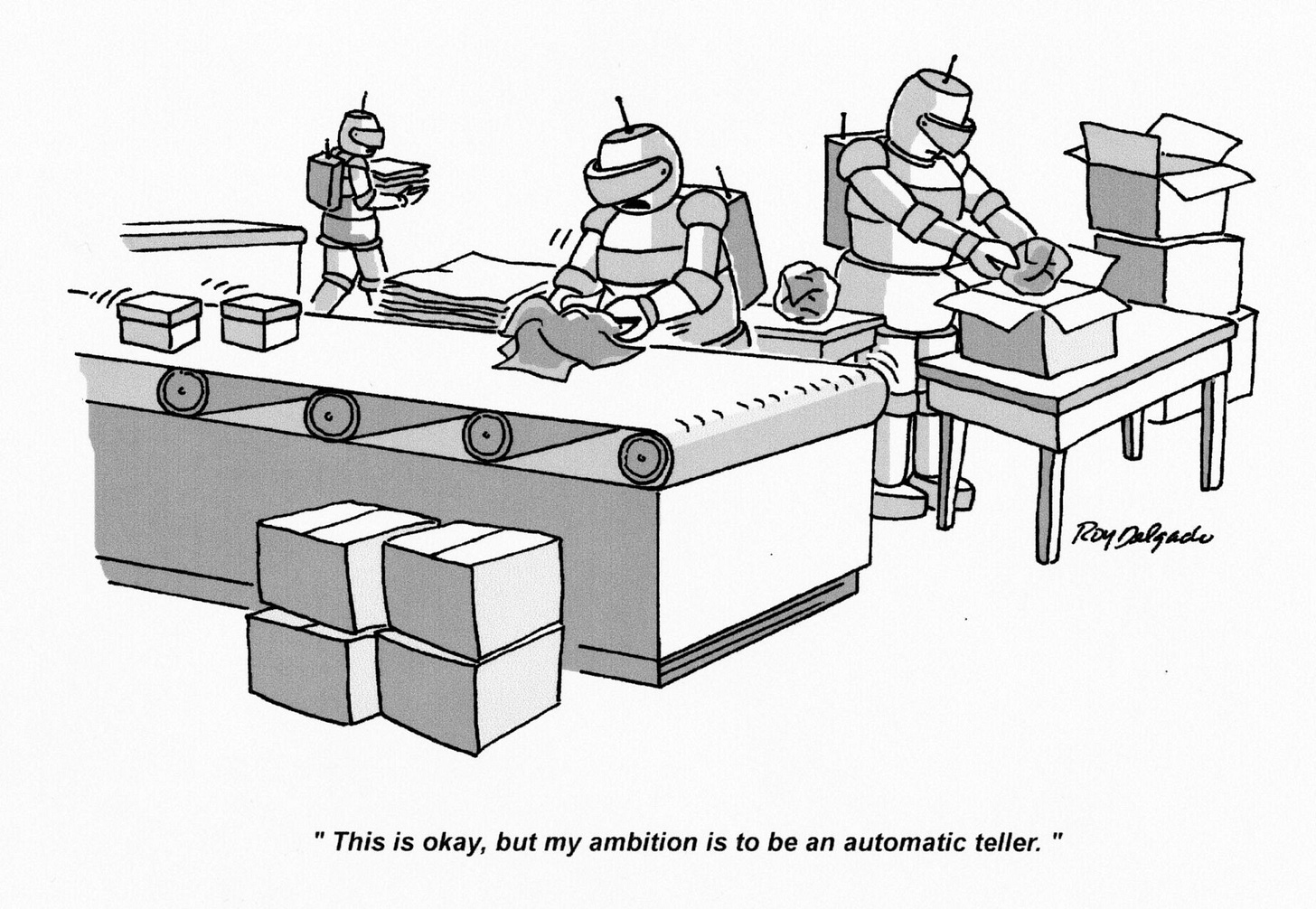

Meme of the week 🤖

Robots have ambitions, too.

A jumping robot inspired by squirrels 🐿️

Researchers at UC Berkeley have studied squirrels to improve robotic agility, demonstrating their one-legged Salto robot jumping onto branches and maintaining balance.

Since its debut in 2016, Salto has served as a platform for robotic mobility research, capable of jumping three times its own height and even bouncing off walls. The latest development allows the bot to land on narrow, unstable surfaces using a combination of a motorized flywheel and adjustable leg forces—techniques adapted from how squirrels absorb landing forces through their shoulders and legs.

This bio-inspired robotics research has practical applications beyond demonstrating impressive acrobatics. Salto’s abilities could lead to search-and-rescue robots that navigate debris, infrastructure inspection bots, and even space exploration robots designed to move efficiently in low-gravity environments.

Co-researcher Justin Yim is now developing a one-legged explorer robot for Saturn’s moon Enceladus, where its jumping capabilities could allow it to cover distances as long as a football field in a single bound.

Locus introduced a new robot type! 🪜

Locus Robotics has introduced Locus Array, an AI-driven system designed for high-density storage and automated fulfillment. Unveiled at ProMat, Array integrates autonomous mobile robots (AMRs) with a tower system and a vision-guided robotic arm to streamline order retrieval and induction.

Array's AMRs use omnidirectional wheels to maneuver in tight warehouse spaces, pulling items from conveyors or flow racks and placing them into bins or cartons. The robotic picking arm, equipped with suction cup end effectors, operates within narrow aisles and can retrieve items from racks up to 10 feet high.

By automating induction, putaway, and decanting for packing, Locus Array aims to address throughput challenges and labor shortages in the healthcare, retail, industrial, and e-commerce sectors. The system promises 99.9% picking accuracy and the potential to reduce warehouse labor requirements by up to 90%.

Locus Robotics, known for its goods-to-person automation, has already facilitated over 4 billion picks and was recognized with a 2024 RBR50 Robotics Innovation Award.