EP.62 INSPECTIONS, THE NEXT FRONTIER FOR ROBOTICS

Humanoid maker from China builds new manufacturing site, a new model from Physical Intelligence & much more...

A robot inspector that moves autonomously! 🔎

Developed by Robotnik, RB-WATCHER is an autonomous mobile robot designed for inspection, surveillance and security applications in both indoor and outdoor environments. It patrols predefined areas, detects people or intrusions, identifies temperature anomalies and collects relevant data.

The Spanish energy company EDP Redes España has integrated these autonomous mobile robots into its electrical substation maintenance strategy to increase safety, reliability, and operational efficiency. RB-WATCHER is designed to operate in harsh environments where human access is limited or risky. It autonomously patrols the substation, monitors equipment, detects overheating, and identifies potential anomalies in real time. The robot collects high-quality data and transmits to the maintenance team, enabling quick response and informed decision-making.

This move reflects a broader shift in the energy sector toward robotic systems that reduce exposure to hazardous conditions and ensure round-the-clock surveillance. The implementation of EDP Redes España, demonstrates how AMRs can support predictive maintenance and improve infrastructure reliability without increasing personnel risk.

Faster, smarter battery pack assembly with robots 🔋

ABB Robotics and JOT Automation have delivered a major manufacturing upgrade for ABB Electrification’s battery energy storage systems, boosting production throughput by 600 percent. The fully automated line, designed with future scalability in mind, is expected to double its capacity again as demand for renewable energy storage grows.

Battery production is a complex, multi-stage process involving sorting, assembly, laser welding, and testing. JOT Automation tackled this challenge by deploying modular robotic cells built around ABB’s six-axis IRB 4600 robot, known for its precision, flexibility, and 25 percent faster cycle times compared to industry benchmarks.

The new solution automates the entire production chain, from material handling and packaging recycling to intricate laser marking and welding, significantly improving efficiency and ergonomics while reducing floor space requirements. Thanks to its modular design, the system can easily scale to meet future production demands, helping ABB stay ahead in the expanding energy storage market.

🦾 Feature sponsorship with ABB Robotics

Unitree opens a new, huge manufacturing facility! 🛠️

Chinese robotics leader Unitree Robotics has opened a new 10,000-square-metre manufacturing facility in Hangzhou, aiming to scale production as China's interest in humanoid robots accelerates. Located just 15 minutes from Unitree's headquarters, the plant will support growth plans over the next three to five years.

Rather than expanding recklessly, the company says it will focus on boosting output through longer working hours and greater efficiency. Backed by the municipal government, the new factory strengthens Unitree’s position in a fiercely competitive robotics market where many rivals struggle with commercialization.

Unitree’s strategy of in-house motor development, strong supplier partnerships, and self-managed assembly has given it a supply chain advantage. Its products, like the Go2 robot dog (priced from $1,600) and the G1 humanoid robot ($16,000), have quickly gained attention, even sparking a rise in "Unitree-concept" stocks in China’s markets earlier this year.

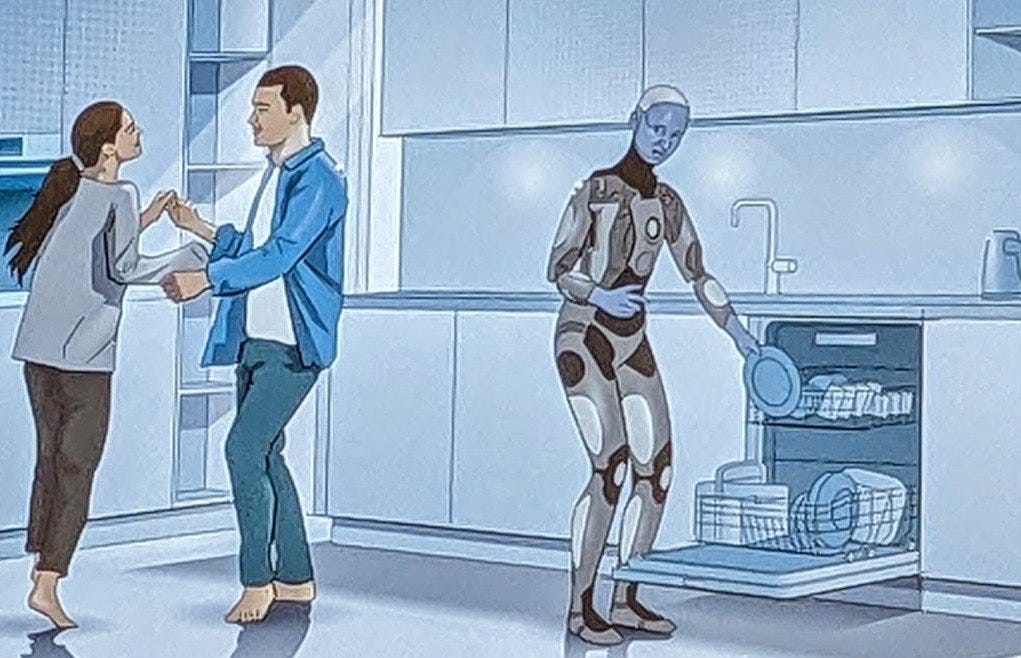

Meme of the week 🤖

Contest: Best caption wins. Send yours!

Soccer playing robots are here! ⚽️

Booster Robotics has unveiled its latest humanoid robots capable of playing soccer, drawing comparisons to professional football stars. While their performance still lags far behind human athletes, the robots demonstrate impressive skills for their stage of development. They can walk omni-directionally, recover from falls and pushes, and actively participate in basic soccer matches.

Designed as a complete, ready-to-use humanoid soccer solution, Booster Robotics' platform includes advanced tools for perception, localization, and decision-making. Developers can also tap into Booster’s reinforcement learning (RL) framework to train custom locomotion behaviors, or quickly deploy RoboCup competition algorithms using their provided demo code.

Through these technologies, Booster Robotics aims to accelerate research and innovation in robotic sports, paving the way for increasingly agile, autonomous, and competitive humanoid players in the years to come.

A new open-world generalization model from PI! 🌍

Despite major advances in robotics, generalization—adapting to unfamiliar environments—remains a critical hurdle. π0.5, a new Vision-Language-Action (VLA) model, is designed to take that challenge head-on.

Unlike robots limited to structured settings, π0.5 can navigate entirely new environments, grasp unknown objects, and reason where items belong. Its strength comes from a co-training approach that combines robotic demonstrations, verbal instructions, web-sourced visual data, and more, allowing it to learn both physical skills and semantic understanding simultaneously.

In tests, π0.5 showed impressive results, successfully completing tasks like cleaning kitchens and bedrooms it had never seen before. Though still evolving, π0.5 points to a future where robots can genuinely adapt to the messy complexity of human life.