EP.77 THIS HUMANOID GETS A 'MOTOR CORTEX'

Cooking robots enter mass production, robots take part in robo ballet, & much more...

Agility Robotics builds a ‘Motor Cortex’ for Digit 🧠

Agility Robotics is giving its humanoid robot Digit a new level of control with what it calls a whole-body control foundation model, essentially a “motor cortex” for robots.

The system is a compact neural network with fewer than a million parameters, trained in NVIDIA’s Isaac Sim physics simulator for the equivalent of decades of practice in just a few days. Once trained, the controller transfers directly to the real-world robot with no extra tuning.

This approach matters because humanoids face unique challenges. Fixed-base robots only have to worry about moving their arms. But a robot on two legs has to constantly balance, decide where to step, and adjust when something unexpected happens. Traditional methods simplify these problems, but at the cost of agility. Agility’s reinforcement learning model handles the full-body dynamics directly, giving Digit much more freedom to adapt.

The interface is also designed to be practical. Instead of programming joint angles or complicated paths, users can simply tell Digit where its hands or torso should move in free space. The model figures out how to coordinate the rest of the body to get there safely and smoothly. This makes it easier to pair with high-level tools like large language models, teleoperation, or scripted tasks.

Agility describes this “motor cortex” as an always-on safety and control layer — something future skills and behaviors can be built on top of.

Circus SE starts the production of cooking robots! 🍝

German startup Circus SE has begun large-scale production of its CA-1 autonomous cooking robots at a new high-volume facility. The company says several units are already rolling off the line in parallel.

Each robot packs over 29,000 components ,roughly the complexity of a small car, and can prepare a meal in just three to four minutes. To keep pace with demand, Circus built its factory with a modular, intelligent setup designed for global scaling.

“This step proves that Circus can not only design breakthrough technology, but also scale it to industrial production at the highest quality levels,” said Nikolas Bullwinkel, founder and CEO. “The era of autonomous nutrition has started — and Circus is leading it globally.”

The Munich-based company designed CA-1 to tackle the labor-intensive food service sector with embodied AI. The system manages its own ingredients with smart silos, uses robotic arms to dispense, cook, and plate meals, and relies on AI-driven computer vision.

Reliability is a core focus. Each CA-1 undergoes more than 150 precision tests, a process the company likens to automotive-grade engineering. Production partner Celestica brings global supply chain and manufacturing expertise to help Circus scale deliveries worldwide.

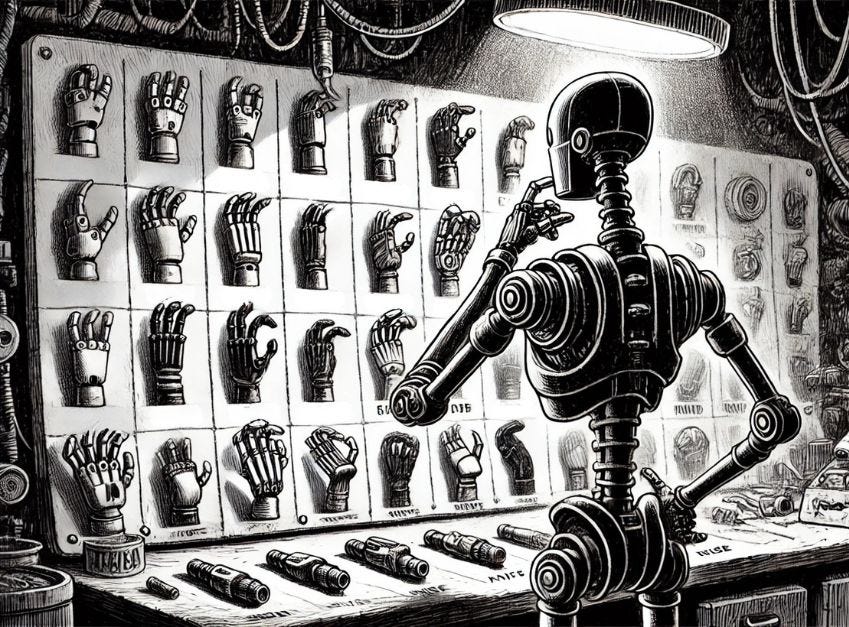

Meme of the week 🤖

RoboBallet - robots learn to move in harmony 🩰

Coordinating multiple robotic arms on a factory floor is notoriously complex, often requiring specialists to spend hundreds of hours programming collision-free task plans. A new system called RoboBallet, developed by researchers at UCL, Google DeepMind, and Intrinsic, promises to change that.

RoboBallet uses a mix of graph neural networks and reinforcement learning, training robots by trial and error and rewarding them for completing tasks quickly and safely. By treating robots and obstacles as nodes in a graph, the system can reason about complex layouts and generate efficient, synchronized movement plans in seconds.

In tests, RoboBallet coordinated eight arms across 40 tasks, producing plans hundreds of times faster than real-time and adapting instantly if a robot failed or the environment changed. “It’s not just about avoiding crashes,” said lead author Matthew Lai. “It’s about achieving harmony at scale.”

The system could transform industries like automotive, electronics, and construction, where teams of robots must work closely together. While the current version focuses on reaching tasks like welding, researchers say future versions will handle sequencing, diverse robot types, and more complex operations.

By open-sourcing the code, the team hopes to accelerate adoption. As co-author Alex Li put it: “In today’s factories, coordinating robots is like solving a moving 3D puzzle. RoboBallet solves it with superhuman grace.”

A robot hand that is almost as good as human one! 🪬

Shenzhen-based Dexcel Robotics has unveiled the Apex Hand, a robotic system that comes unusually close to replicating the versatility of the human hand. With 21 degrees of freedom (DoF) and advanced tactile sensing, it’s one of the first robotic hands capable of performing everyday tasks such as using a smartphone with one hand, checking a pulse, or controlling a computer mouse.

Each finger can apply about 2.5 kilograms of force, with the hand lifting up to 30 kilograms in total. Its precision is measured at 0.1 millimeters, and near-zero backlash ensures smooth movement.

A standout feature is Dexcel’s proprietary electronic skin: a flexible, brain-inspired material that delivers ultra-fast tactile processing. With sub-millisecond latency and refresh rates above 1,000Hz, it enables lifelike sensitivity while avoiding the durability trade-offs of traditional rubber-based skins.

The Apex Hand is also among the few systems to achieve a perfect score on the Kapandji test, which evaluates finger-to-finger mobility.

Founded by Yang Sicheng (ex-Tencent Robotics X) and Li Wangwei, Dexcel has deep academic and industrial experience, with nearly 50 research papers and 100 patents between them. The company recently closed an eight-figure RMB angel+ funding round, led by Fibonacci VC.

For decades, dexterous robotic hands have been confined to research labs. According to Yang, the sweet spot is 21 DoF, enough to match human capability without adding costly, hard-to-control complexity.