EP.78 A HUMANOID MAKER RAISED $1B IN FUNDING

First industrial humanoid robot from the UK, a new open-source OS for robots & much more...

Figure raises $1B+ and hits $39B valuation! 💰

The race to commercialize humanoid robotics just hit a new benchmark. San Jose–based Figure has raised over $1 billion in its latest funding round, pushing the company’s valuation to $39 billion, a number that puts it among the most valuable private robotics startups in the world.

The Series C, led by Parkway Venture Capital with backing from Brookfield Asset Management, Nvidia, and Intel Capital, marks the company’s largest raise to date. Figure says the fresh capital will go toward scaling its humanoid fleet, accelerating robot training infrastructure, and expanding data collection pipelines.

Founded in 2022, Figure has quickly positioned itself as a frontrunner in humanoid robotics, raising nearly $2 billion in just three years. Its robots are designed to take on tasks in warehouses, factories, and other industrial environments, spaces where labor shortages, safety risks, and rising costs are driving demand for automation.

CEO Brett Adcock has been vocal about investor appetite, calling Figure “the most sought-after stock on the private market” earlier this year. At the same time, the company has aggressively controlled how its shares are traded, issuing cease-and-desist letters to unauthorized secondary brokers.

The new valuation underscores a broader trend: investors are betting heavily that humanoid robots will soon become not just a concept demo, but a scalable workforce solution. With competitors from China to Silicon Valley racing ahead, Figure’s next move will be watched closely, not just by investors, but by every company weighing how robots might reshape their operations.

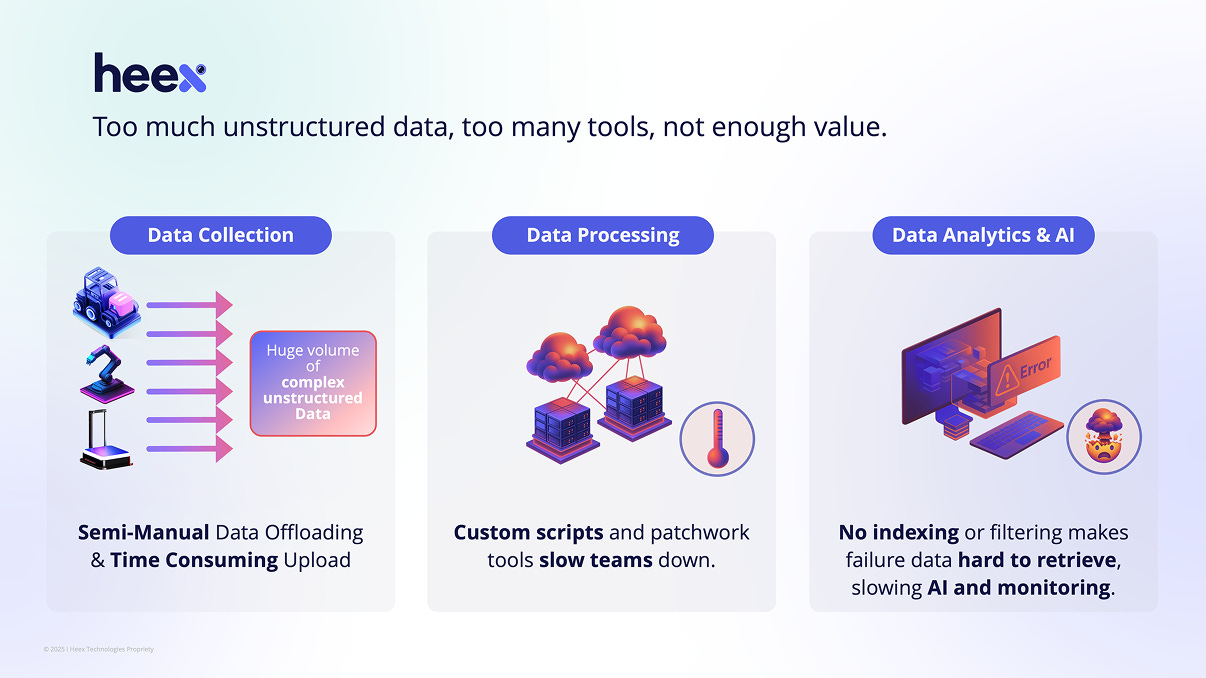

The Robot Data Paradox: Too Much Information, Too Little Access

Autonomous systems generate huge volumes of sensor data every day, from cameras, LiDARs, radars, and more. But here's the irony: most never get used.

Why? Because it's buried in Terabytes of noise, expensive to store, and even harder to find important parts when needed. Engineering teams often spend hours digging through irrelevant logs or dealing with clunky configurations just to find the few seconds of meaningful information they actually need.

This disconnect between data generation and data usability is often called the Robot Data Paradox. It’s not just a major roadblock, it's a fundamental barrier to scaling operations . Valuable insights are lost, iteration slows down, and progress stalls.

At Heex Technologies, they've cracked this paradox, by capturing the moments that matter while maintaining comprehensive backup when you need it. No need of choosing between overwhelming data volumes or risky sampling. Stay Tuned to see how Heex is flipping the paradox!

More to come soon!

Robotiq launches new lean palletizing solutions! 📦

Robotiq has introduced a new way for manufacturers to automate palletizing with the launch of its Lean Palletizing Experience, along with two new systems: PAL Ready and the PAL Series.

Robotiq’s new approach aims to change that by making palletizing more like a repeatable product than a one-time engineering project.

Manufacturers can test and design their palletizing setup using Robotiq’s online tools before committing to equipment. From there, they can see the systems in action through Robotiq’s partner network, and finally deploy them on the factory floor.

Two options are available. PAL Ready is a plug-and-play palletizing cell that arrives fully assembled, tested, and ready to work. It can be installed in less than a day and includes built-in safety features, mobility for moving between lines, and Robotiq’s PowerPick vacuum gripper for handling different box types. For manufacturers who want more flexibility, the PAL Series offers a modular system that can be expanded step by step across multiple lines or facilities, while keeping the same software and user experience.

“Manufacturers shouldn’t have to choose between speed and scalability, we’re giving them both,” said Samuel Bouchard, CEO of Robotiq. “With PAL Ready and the PAL Series, palletizing becomes a proven, repeatable process instead of a complicated project.”

Robotiq, known globally for its collaborative robotics, focuses on freeing workers from repetitive manual tasks and making automation more accessible.

Meme of the week 🤖

UK robot maker unveils their first humanoid robot! 🤖

London-based robotics startup Humanoid has officially stepped onto the stage with the launch of its HMND 01 Alpha, a dual-armed mobile manipulator built for industrial use.

The HMND 01 Alpha is already being trialed in warehouses, logistics hubs, and retail environments, where it can handle tasks like picking, kitting, loading and unloading, and machine feeding. Standing 220 cm tall, the robot can travel up to 7.2 kph, carry 15 kg with both arms, and reach from the floor to 2 meters high, making it flexible for a wide range of material-handling scenarios. It features 29 active degrees of freedom, AI-driven reasoning, and interchangeable end-effectors, from a dexterous five-fingered hand to a parallel gripper.

Under the hood, Humanoid leans on a proprietary training pipeline that combines 360° simulation with real-world data flywheels. The company claims this approach enables development at twice the speed and half the cost of traditional methods.

Their CEO Artem Sokolov founded Humanoid in 2024 and has so far raised $50 million in founder-led capital. The company plans to follow up with a Beta version in 2026, building on Alpha’s field tests to refine functions and add capabilities. For customers, the robots will be offered through a robotics-as-a-service (RaaS) model, lowering upfront costs and encouraging adoption.

With industrial labor shortages mounting and global robot density climbing, Humanoid’s debut adds another ambitious player to Europe’s fast-growing humanoid robotics scene.

OpenMind launches an open-source OS for robots 👨🏼💻

San Francisco–based OpenMind has released the beta version of OM1, which it calls the world’s first open-source, robot-agnostic operating system. The goal: to give any robot, from humanoids to drones, the ability to perceive, reason, and act without being tied to proprietary ecosystems.

For decades, robotics has been fragmented by closed software, hardware-specific systems, and steep learning curves. OpenMind wants OM1 to be the universal layer that ties everything together. At its core is FABRIC, a decentralized coordination system that provides secure machine identity and allows robots to collaborate across environments.

The beta release comes loaded with features. OM1 works across hardware types, integrates with major AI models (OpenAI, Gemini, DeepSeek, xAI), and supports natural communication through speech and vision. It ships with preconfigured agents for popular robots like Unitree’s G1 humanoid and TurtleBot, and includes SLAM-based navigation, lidar support, and Gazebo simulation tools. Developers can even build voice-controlled quadrupeds in minutes or prototype humanoids with language-based interaction.

The company argues that robotics has reached a tipping point: billions have gone into hardware, but without a shared intelligence layer, robots remain underutilized. By open-sourcing OM1 on GitHub, OpenMind hopes to lower barriers to entry, accelerate interoperability, and foster a developer ecosystem that makes robotics adoption as fast and flexible as software development.