EP.47 APPLE JOINS THE ROBOTICS RACE

Apptronik and Google develop robot brain, a new hand for humanoids & much more...

🚨 Starting with 2025 - the edition of the newsletter will be published every week instead of every two. More robot stories for you!

Apptronik partners up with Google DeepMind! 🧠

Apptronik has announced a partnership with Google DeepMind to combine advanced AI with humanoid robotics. The collaboration aims to create intelligent, versatile, and safe robots capable of helping people in dynamic environments.

Apptronik’s Apollo humanoid robot, designed for physically demanding tasks in industrial settings, is a key part of this initiative. Standing 5 feet 8 inches tall and weighing 160 pounds, Apollo is already being tested by companies like GXO Logistics and Mercedes-Benz. It features bespoke linear actuators that earned Apptronik a 2024 RBR50 Robotics Innovation Award.

Google DeepMind brings its AI expertise to the partnership, including experience with foundation models like Gemini and robotics platforms such as ALOHA Unleashed. Together, the companies plan to push the boundaries of what humanoid robots can achieve.

New construction materials created by robots! 🏗️

Researchers at the University of Kassel have developed an innovative process for creating sustainable construction materials from wood veneers using ABB robots.

The process involves winding 0.5-millimeter-thick wood veneers around formwork elements, creating lightweight ceiling panels and support pillars. These structures are robust, stable, and ideal for modernizing existing buildings or adding new stories. By leveraging wood—a renewable resource—the method offers a sustainable alternative to traditional materials like carbon fiber or aluminum.

ABB industrial robots play a crucial role in the production process, precisely applying veneer tape with millimeter accuracy. The robots use polyurethane glue and high tensile forces to ensure each layer is smoothly wound, aligning with the wood's natural grain for optimal load-bearing properties. This precision would be impossible using conventional methods or presses.

The University of Kassel has collaborated closely with ABB to integrate robotics into its construction research. ABB’s RobotStudio and Grasshopper software allows researchers to plan, simulate, and execute complex designs, enabling the creation of intricate, lightweight structures. From triangular to asymmetrical shapes, the possibilities for architectural creativity are vast.

Read more here → Full success story

New hand for Sanctuary AI humanoid ✊🏼

Sanctuary AI has showcased its robotic hand’s ability to perform advanced in-hand object manipulation. The 21-degree-of-freedom (DOF) hand uses miniaturized hydraulic valves, offering far greater power density than traditional electric systems. Sanctuary’s recent tests achieved over 2 billion cycles without leaks, a major milestone for hydraulic reliability.

CEO James Wells emphasized that dexterity is key to unlocking the market for general-purpose robots. The company’s Phoenix humanoid robot, powered by its Carbon control architecture, is being trained with enriched behavioral data from these manipulations to enhance real-world interactions.

Sanctuary AI has raised $140 million to date and continues to focus on manipulation technologies for Phoenix. While mobility options like bipedal or wheeled bases remain in development, the company’s modular robotic hands are designed for versatile integration with humanoid and non-humanoid robots alike.

Apple joins the humanoidal robots race! 🍎

Researchers from Carnegie Mellon University and Apple have developed a robot collision avoidance system. They called it ARMOR and they implemented it on the Fourier GR-1 robot.

ARMOR is a new egocentric perception system designed to improve the spatial awareness of humanoid robots. By placing Time-of-Flight (ToF) depth sensors on a robot’s arms, ARMOR eliminates blind spots and provides high-coverage depth perception. This setup allows robots to move more dynamically and safely in complex environments.

Their system includes ARMOR-Policy, a transformer-based motion planning framework trained on over 86 hours of human motion data. This advanced software helps robots plan their movements, making them more efficient and collision-free. Compared to traditional perception systems like head-mounted or external cameras, ARMOR achieves a 63.7% reduction in collisions and a 78.7% increase in task success rates.

The system also delivers impressive speed improvements, with a 26× reduction in computational latency compared to older sampling-based planners.

Meme of the week 🤖

Robots are just software!

Said no one ever...

Robotics operates at the edge of software and hardware.

There are no robots without software, no robots without hardware.

Building and deploying SLAM workflows [WEBINAR] 📺

This webinar explores SLAM techniques, including front-end and back-end algorithms, applications in automotive and robotics, and implementation challenges. Participants will learn about SLAM algorithms in MATLAB® and Simulink® with demonstrations of sensor fusion, pose optimization, and ROS deployment.

Key Topics:

Implementing efficient monocular SLAM with real-world data in MATLAB.

Techniques with pose graph optimization.

Factor graph-based workflows, including monocular visual-inertial systems (VINS-Mono).

Integrating SLAM with MATLAB and ROS.

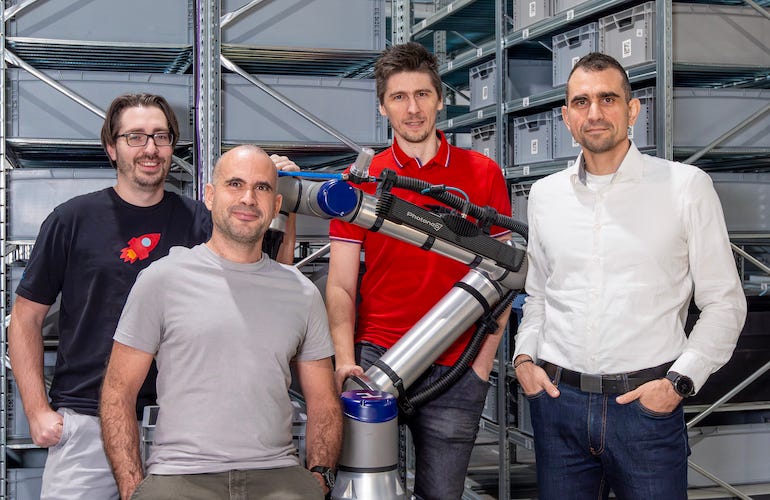

Zebra Technologies to acquire Photoneo 📸

Photoneo, a leader in 3D vision and AI robotics, has announced its acquisition by Zebra Technologies.

Photoneo’s proprietary parallel structured light technology delivers high-speed, high-resolution 3D machine vision solutions. These sensors are widely used in robotic arm applications and seamlessly integrate with major manufacturers. Combining Photoneo’s 3D vision expertise and Zebra’s advanced sensor technology and AI image processing will enable new opportunities in industries such as automotive, logistics, and manufacturing.

Following the acquisition, Photoneo Brightpick Group will rebrand as Brightpick and remain an independent entity. Sale proceeds will fuel the global expansion of its AI-driven warehouse automation robots. Brightpick’s flagship product, the Autopicker, autonomously picks and consolidates orders directly in warehouse aisles, revolutionizing fulfillment processes.